Welcome to visit our factory at any time !

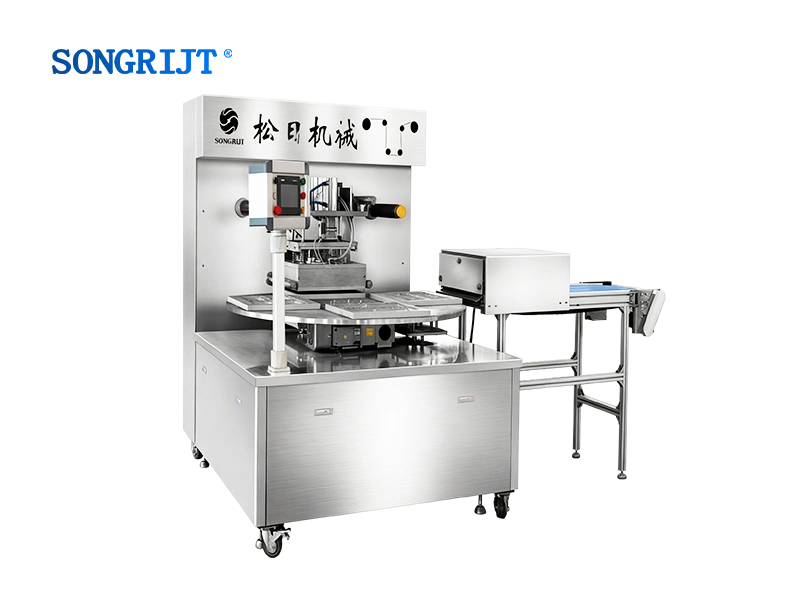

It adopts a programmable controller and,in combination with a color touch scren,can achieve human-machine interface dialogue.The actions of eachpart and control parameters can all be set and modified by the controller.

| Model number | SR-1200 |

|---|---|

| Maximum box size(mm) | Customization |

| Maximum film width (mm) | Customization |

| Maximum film diameter(mm) | 280 |

| Packing speed(box/h) | Approximately 500–700 |

| Power source | 380V/50Hz |

| Working air pressure(Mpa) | 0.6-0.8 |

| Total power (kW | 8 |

| Gas replacement rate | 200m³/h |

| Machine weight (kg) | 700 |

It adopts a programmable controller and,in combination with a color touch scren,can achieve human-machine interface dialogue.The actions of eachpart and control parameters can all be set and modified by the controller.

All molds are made of hexagonalaluminum-magnesiumally,which is of high strength,hard and corrosion-resistant,and meets the standards for foodhygiene equipment selection.

The whole machine is made offood-grade 304 stainlesssteel,with a frame structure that is stable and not prone to deformation.4.It adopts imported acum pumps,which feature fast pumping speed,stable quality and low residual oxygen content.

Suitble fo bef cold meat aquatic produts,ham and other products packaging.

28 years. For all these years, we have been focusing on manufacturing vacuum packaging machines.

Yes, We are factory, all machine is made by ourself and we can provide customize service according to your requirement.

Our warranty is 1 year, all machine part can be replaced for free within 1year if broken(not including man made).

Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

It takes almost 30 days to complete the production, after which we will arrange for shipment.

We will pack your order according to your requirements as follows

We will ship by sea, land, and air according to your requirements.