Welcome to visit our factory at any time !

I. Solution Background

Durian flesh is rich in moisture and sugar, making it prone to oxidative browning and microbial growth at room temperature, leading to spoilage within 2-3 days. Its strong odor is prone to leakage, and the soft flesh is susceptible to compression damage. Traditional packaging (cling film, ordinary cardboard boxes) struggles to address the three major pain points: preservation, odor isolation, and damage prevention. Vacuum packaging can isolate air and inhibit spoilage. Combined with specialized materials and processes, it can simultaneously solve the core challenges in durian transportation and storage, expanding the sales radius.

II. Core Problems

1. Oxidative browning and microbial growth, resulting in a very short shelf life;

2. Odor leakage, affecting the storage and transportation environment;

3. Soft flesh, susceptible to compression damage;

4. Lack of suitable packaging solutions for odor isolation and compression resistance.

III. Specific Solution

(A) Packaging Material Selection

Utilize a "PET/EVOH/AL/PE composite film". The EVOH layer enhances odor and oxygen barrier properties, the AL layer blocks light and moisture, and the PE layer ensures heat seal integrity. The outer PET layer improves compression and abrasion resistance. Customize specifications based on needs:

· Retail packs (100-200g): Include a built-in cushioning bubble layer to prevent flesh compression.

· Wholesale packs (500-1000g): Incorporate rigid internal supports to enhance overall compression resistance.

· Label packages with "For Durian Use" and "Requires Cold Chain" to indicate storage conditions.

(B) Process Optimization

1. Pre-treatment: After pitting and cutting, rapidly cool the flesh to 0-4°C (to avoid accelerated spoilage at high temperatures). Gently wipe off excess surface juice to reduce breakage and juice overflow during vacuuming.

2. Core Process:

o Gentle Loading: Avoid stacking and compressing the flesh; reserve about 1/5 of the package space.

o Moderate Vacuuming: Control vacuum degree between 0.06-0.08MPa (lower than for sauces to prevent flesh deformation); evacuation time 15-25 seconds.

o Low-Temperature Heat Sealing: Heat seal temperature 140-180°C, with a short sealing time (1-2 seconds) to avoid high temperatures affecting flesh texture.

o Rapid Cooling: Immediately air-cool after heat sealing to strengthen the seal while maintaining low flesh temperature.

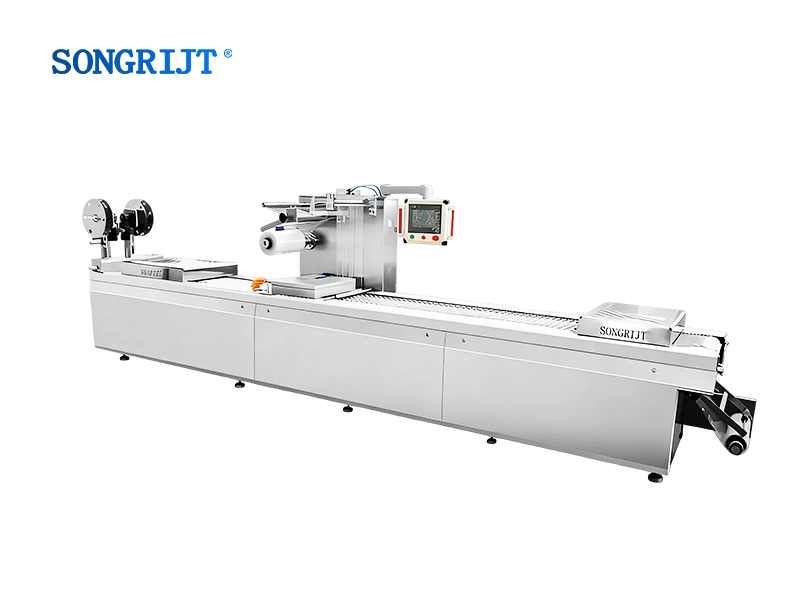

(C) Equipment Selection

1. Small Modified Atmosphere Vacuum Packaging Machines: Our company recommends models SR380 and SR1200, suitable for small processing plants/supermarkets/stores. Equipped with a "Gentle Evacuation" mode; manual loading assistance helps avoid flesh damage. The unit price is low, making them cost-effective.

2. Large Modified Atmosphere Vacuum Packaging Machines: Our company recommends models SR720 and SR555, suitable for large-scale production. Feature automatic gentle loading devices and cold chain linkage modules. Can package 400-800 boxes per hour. Unit price: ¥120,000 - ¥300,000. Reduces labor costs and loss. Offers significant production volume and profit margins.

(D) Quality Control

1. Seal Integrity & Odor Barrier Testing: Use water immersion method to check for leaks. After sealing, let packages sit for 24 hours and conduct sensory tests for odor leakage.

2. Microbiological Testing: Regularly test total bacterial count, molds, etc., complying with the standards for flesh-based products in GB 10789-2021 "Beverage General Standard".

3. Sensory & Integrity Inspection: Check for intact flesh, normal color (light yellow to golden yellow), and absence of off-odors.

IV. Cost and Benefits

(A) Cost Composition

· Packaging Materials: Composite film cost per bag is higher than standard materials; single bag cost ranges from ¥0.5 - ¥3 (including cushioning structures).

· Equipment Investment: Choose semi-automatic/fully automatic models based on production scale, paired with cold chain equipment (e.g., cold storage, refrigerated trucks).

· Operational Costs: Include low-temperature pre-treatment and cold chain transportation expenses. Labor costs can be reduced by 30%-50% depending on automation level.

(B) Core Benefits

1. Shelf life extended to 15-30 days (under cold chain storage), a 5-10 fold increase compared to traditional packaging, significantly reducing spoilage loss.

2. Complete odor isolation and damage prevention, enhancing product transportation safety and consumer experience.

3. Breaks geographical limitations, enabling long-distance transportation and expanding sales channels (offline supermarkets, e-commerce, etc.).

4. Standardized packaging enhances brand image, allowing for a premium of 20%-30% compared to bulk durian.